ONI Rhytemper® Special builds

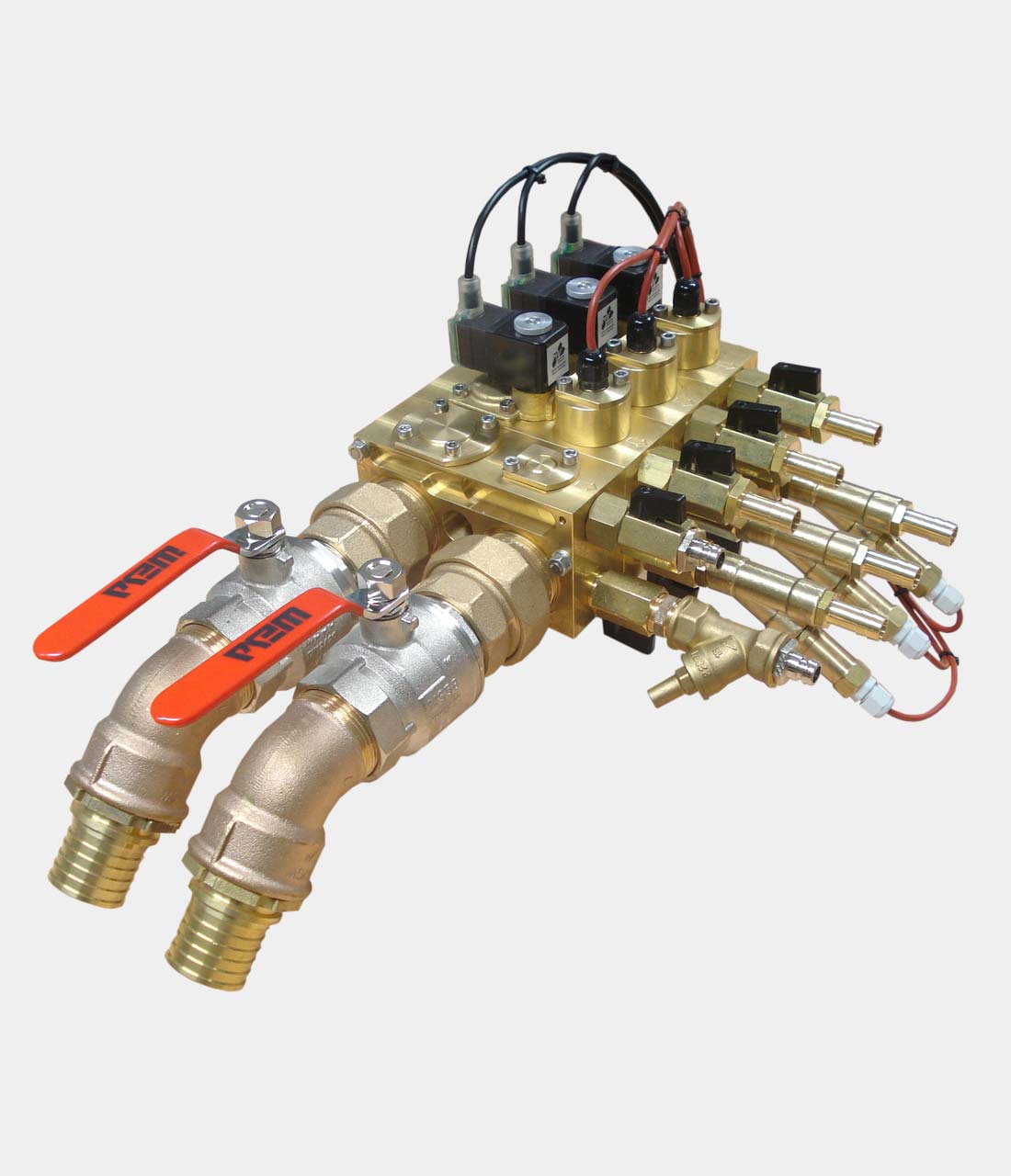

Individual connection unit

Individual connection unit

- Feed line temperature and pressure measurement

- Switchover of different media temperatures

- Filtering to keep contamination out of the tooling

- Pressure increase

| Power range | 3 – 54 kW | ||

|---|---|---|---|

| Max. water feed line temperature | up to 160 °C | ||

| Group circuit connections | 1, 1¼, 1½, 2 inch |

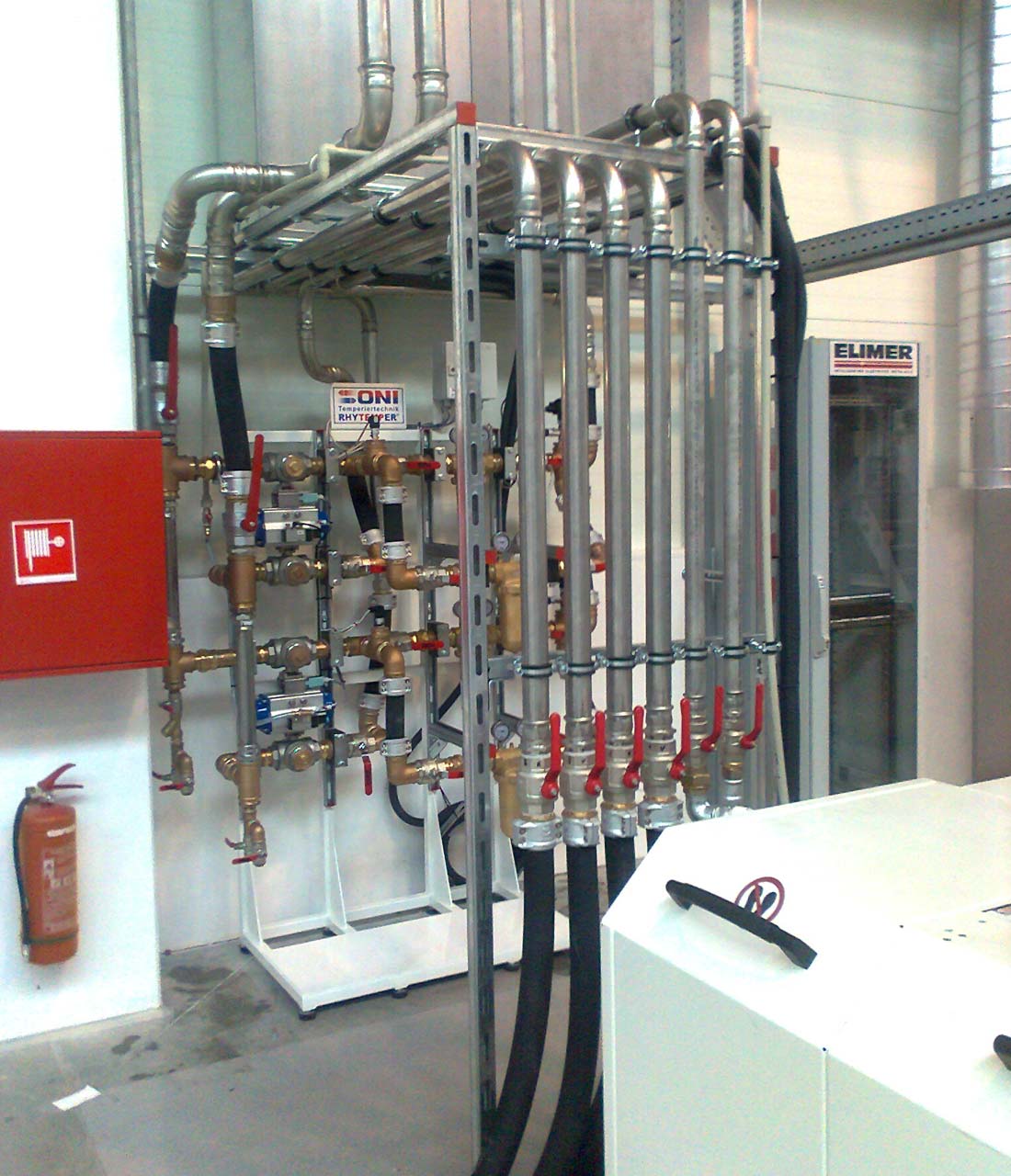

Special applications require special solutions!

As required, we tailor our modules precisely to your needs – perfectly planned, tuned and built for the respective process.

Unlike conventional temperature control systems, a FlexControl series RHYTEMPER® system can, for example, manage without any heating power in the process. This saves 100% of the typical incidental heating energy costs. Beyond this the cooling energy fraction, necessary for compensating control inaccuracies in temperature control equipment, is dispensed with.

A further plus is the interruption of the temperature control medium when opening the mould. This not only reduces energy consumption but also improves the process conditions for each new injection cycle and hence for each fresh occupancy of the mould.

Doing away with a recirculation pump in the RHYTEMPER® system immediately leads to several savings impacts. Apart from savings on expensive electricity, recooling energy for the lost pump heat is avoided.

All in all, RHYTEMPER® systems thereby reduce the heat energy requirement to zero, the cooling energy expense to that which is strictly necessary and with it the costs for the tooling temperature control to an absolute minimum.

Getting to series production conditions in the shortest time is extremely important for the plastics processor. Depending on tooling and shot weight, a start-up phase without pre-temperature regulation is not possible.

With the RHYTEMPER® temperature control unit, the start-up period until the quality-compatible operating temperature is reached is massively shortened! Unnecessary waiting times due to manual tooling warm-up are thereby avoided. Beyond this, individual tooling zones which require permanent thermal heat can be supplied via the pre-heat unit as required. The organisation of the requirement orientated pre-heating in start-up operation as well as providing the individual tooling zones with thermal heat is done via the central RHYTEMPER® regulation unit. The RHYTEMPER® temperature control unit thereby makes an important contribution to the best possible utilisation of process times and hence piece cost optimisation.