ONI Rhytemper® HotPulse

Impulse temperature control in die casting for high-temperature applications

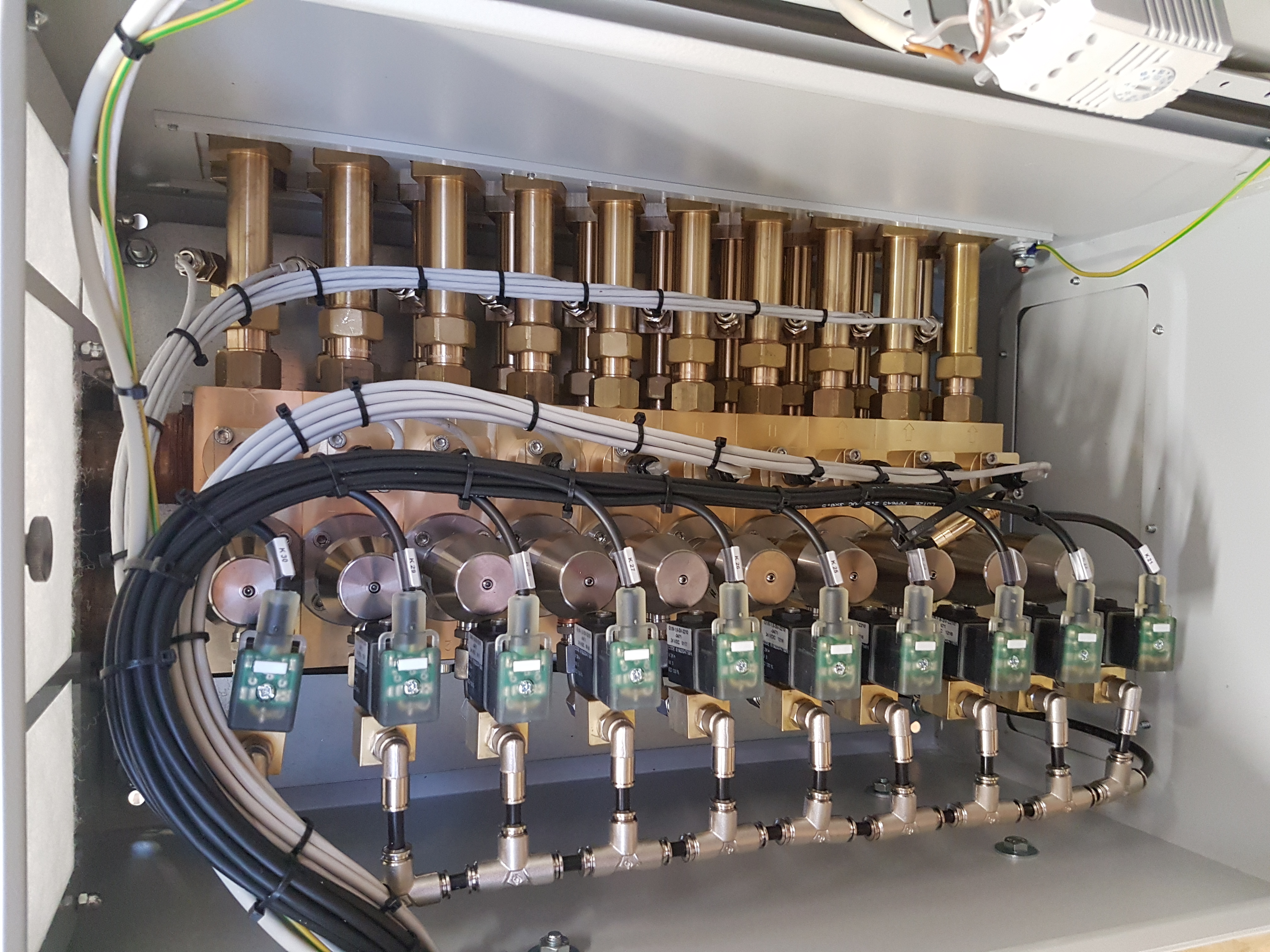

- Compact system of brass blocks

- Includes Profi visualisation unit with 10.4 inch touchscreen control panel, graphic process data display, tooling data storage and USB connection for data transfer

- Heat level and flowrate monitoring of an unlimited number of temperature control circuits

- Automatic matching of the cooling pulse to the current pressure diecasting process

- Interruption of the heat extraction during the mould filling phase and the tool movement

- Greatest possible flowrate through 1½ inch water connection

- Flowrate measurement by means of turbine

- Media supply possible via temperature control unit, technical heat source or the central cooling network

- Space saving machine integration

- Installation close to tooling

- Individual circuit flowrate calibration

| Circulation control | pneumatic valve | ||

|---|---|---|---|

measuring principle | turbine | ||

| Measurement method | 0,3 – 40 l/min | ||

Max. Mediumstemperatur | 160°C (320°F) | ||

| Measurement medium | water | ||

| Main media flow connection | 1 ½“ IT | ||

| Consumer circuit connection | 1 ½ inch IT | ||

| Max. permissible operating pressure | 16 bar with160 °C (320°F) |

RHYTEMPER® HotPulse – multiple circuit temperature control for the highest moulded part quality

In contrast to conventional temperature control systems the RHYTEMPER® HotPulse can be installed close to the tooling, protected in a pressure diecast cabinet on the pressure diecasting machine. This enables the exact temperature and flowrate recording and regulation. The diecast cabinet acts as a robust protective housing for the sensor system and the valves.

The modular design with preassembled, housed-in manifold blocks in addition to pre-wired electronic boxes enables space saving installation of the RHYTEMPER® HotPulse close to the tooling. The individual modules, whose number of circuits is tailored to the respective application, are connected to each other and to the main controller via a bus system.

Standards have been agreed with selected pressure diecasting machine manufacturers for the installation of the RHYTEMPER® HotPulse modules directly in the machine manufacturer's works. Thus in the case of new machines the system can already be integrated by the manufacturer at their works and delivered together with the machine – economic temperature control can be that simple!

The operator interface of the RHYTEMPER® HotPulse is simply and clearly designed. The optimum settings for economic temperature control can be undertaken in just a few steps.

The heat level of each individual temperature control circuit is set individually to the respective moulded part-specific requirement and displayed in a coloured bar. Adaptation of the heat level is done quickly and simply via the setting function "hotter" or "colder".

Each temperature control/tooling circuit is allocated an appropriate mode of operation (mode) which is saved as a dataset and can be reactivated at any time.

Furthermore, with the RHYTEMPER® HotPulse numerous other special functions and setting options are available to the experienced application technician.